Aluminium casting moulds are much more affordable and effective than you think. Here we come up with the information that not only explains to you about the procedure but also helps you out while explaining the full term.

What is casting?

In shaping and jewelry creating, the casting could also be a way during which a liquid metal is somehow delivered into a mold that contains a negative impression of the supposed form. The metal is poured into the mold through a hollow channel mentioned as a disorder. The metal and mold square measure then cooled, and also the metal half (the casting) is extracted. Casting is most often used for creating complicated shapes which will be tough or uneconomical to make by other ways

ancient techniques embody lost-wax casting (which could even be additional divided into centrifugal casting, and vacuum assist direct pour casting), plaster mold casting, and sand casting.

The modern Aluminium casting moulds method is split into 2 main categories: expendable and non-expendable casting. it's additionally dampened by the mold material, like sand or metal, and gushing methodology, like gravity, vacuum, or atmosphere.

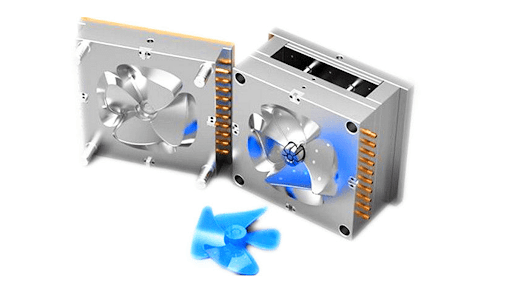

Die casting

In the die casting method, liquid or “molten” metal is forced into a die underneath high. during this case, “die” refers to the steel mold created to form a particular product that will be created. Following the pour and injection into the mold, the melted metal solidifies and is off from the mold. once the metal cools, the gating material gets removed and a product has been manufactured! The steel mold will then be closed and ready for future “shot,” which permits it to be reused forthwith. The cycle creating a die solid half will be from thirty seconds to 1 minute, creating the method very quickly.

Pros of Aluminium casting moulds:

Die casting will provide you with the chance to make robust, custom, advanced elements by the thousands or millions through an associate direct investment that’s followed by the associate economical method. Here are a couple of of the execs of die casting:

- Systematic method -Once you’ve created the die for your half, it's economical to breed thousands, many thousands or perhaps ample individual elements with very little machining or further.

- Consistent elements -production could be a perk, however, therefore, is that the consistency that comes with it. attributable to the exactitude in die casting, you’re certain to get consistent, repeatable results, that is vital once you’re producing specific metal elements.

- Custom ending choices -whether or not you’re finding out a sleek or rough-textured finish, die-forged elements are often designed to possess a particular look.

- Ductile -additionally to the finishing choices, there is a range of customization choices the thickness of the half, as an example, furthermore because of the overall quality. Die forged elements are often straightforward or advanced the quantity of detail is versatile, creating die casting an answer for making a range of elements.

- Long-lasting -period -Die forged elements don't seem to be welded or joined along, however rather made of one mold. This makes them stronger than several different elements — they’re famous for being sturdy. a part of the rationale they’re sturdy is that they’re heat-resistant and dimensionally stable. These qualities and characteristics build it straightforward to envision why they're recognized for lasting longer. We’ll provide additional data concerning however their service life compares to different casting processes within the section below.

Aluminium die-casting Vs plastic molding

The distinction between All dies forging and plastic molding comes within the resulted components die-cast components square measure manufactured from metal Aluminum, compared to the plastic components that result from this kind of molding. whereas the speed of the processes is extremely similar the liquid plastics square measure injected into molds, rather like the liquid metal of die casting the ensuing components square measure completely different, because of their material composition.

Die forged components have a way higher tolerance for extreme temperatures and higher electrical properties than the Aluminium casting moulds components. They even have nearer tolerances and square measure illustrious for being a lot of sturdy and stable when put next to plastic components. Another issue to contemplate is that the holes that square measure required to assemble the piece to alternative components. as an example, die-forged components will have a hole forged or trained directly into them, which may function an immediate thread for screws. With plastic components, a metal insert would wish to be other to accommodate a thread for a screw, that adds a step, and ultimately, a cost