With regards to making your parts, you have a significant choice to make. Would it be advisable for you to make your parts utilizing plastic injection moulding Manufacturing or aluminum pass on casting? To enable you to choose, we should take a look at the significant benefits and limitation of each.

Die Casting versus Injection Moulding:

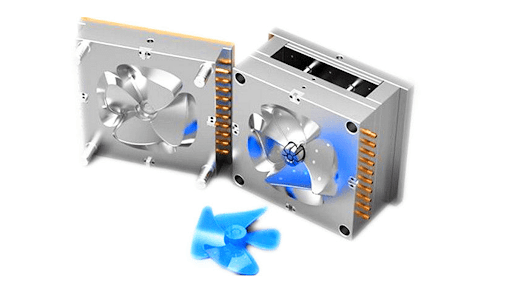

The way toward making a section is essentially a similar whether you are utilizing pass on casting or injection moulding. You make a pass on or shape as the part you need to make. You at that point liquify the material and utilize extraordinary strain to infuse it into the die/form. You at that point cool the pass on/shape with inner cooling lines and die splash on the bite the dust holes. At last, you open the pass on and eliminate the shot.

Despite the fact that there are a few varieties in method, the significant contrast between die casting and injection moulding is that pass on casting uses some sort of metal, regularly an aluminum composite, as the crude material, while injection moulding uses plastic or polymers.

Which would it be a good idea for you to utilize? It needs to be clear immediately that in case you use injection moulding, you will wind up with plastic parts and in case you use bite the dust casting, you will wind up with metal parts. In case you know what kind of parts you need to wind up with, you realize immediately which to utilize. However, in case you don't know which material is better for you and your organization's items browse on.

Advantages of Plastic Injection Moulding:

- Creation is faster because of greater adaptability in the cut cycle

- Plastic Injection molds can oblige diverse plastic or polymer materials

- Fillers can be utilized in plastic molds to expand quality

- Effective cycle with exact completions

Advantages of Aluminum Die Casting

- Effective cycle with a serious extent of precision

- No requirement for optional activities

- Confounded plans can be all the more effortlessly cast

- Produces greater items with better resilience that will last more

Aluminum Die Casting versus Injection Moulding:

So for what reason would you pick injection moulding over pass on casting? In case you are hoping to deliver a ton of parts economically, injection cut may be the best approach, as work and material expenses are genuinely light, despite the fact that it is essential to remember that the expense of the plastic injection moulding machines themselves and any auxiliary hardware can be genuinely costly.

In case exactness in configuration is a high need, or you are hoping to make numerous mind boggling parts in a short timeframe outline, die casting is quite often the favored choice. Regardless of whether you are planning less difficult parts, numerous individuals favor the conspicuous sentiment of solidness and quality you get in a strong metal part over a plastic part.

Contact Plastic Injection Moulding Manufacturing for your Casting Needs:

When you have concluded that aluminum die casting is the best approach for all your part produce needs, the following stage is to contact the professionals. We have been rejuvenating incredible part plans for more than 70 years with cutting edge gear and exceptionally prepared designers, ensuring you get the most ideal item produced in the most proficient manner possible.

An Australia based organization that does the entirety of our pass on casting in our bleeding edge pass on casting plant and has made top notch parts for businesses going from guns to broadcast communications to clinical gadgets and that's only the beginning. Organizations that need casting work as for plastic injection Moulding manufacturing.

Normal Overmoulding Materials and their Advantages:

ABS (Acrylonitrile Butadiene Styrene):

ABS is an industry picked material in over-moulding cycles to arrive at specific prerequisites in applications, such as, customer gadgets or car parts. ABS is financially savvy underway and gives many worth included advantages like:

- Low softening point which makes it simple to use in measures like injection embellishment or 3-D printing

- Low warmth and power conductivity for items requiring electrical protection insurance

- Deeply recyclable

- Reflexive, smooth, surface completion that can likewise be viable with an assortment of pastes or paints

- Takes color effectively so as to meet specific undertaking details

- Resistant to synthetic disintegration and physical effects on withstand both ecological requests and weighty use.

- Effectively pliant with incredible elasticity

PMMA (Polymethyl Methacrylate Acrylic):

PMMA is a conservative material utilized for applications requiring brilliant optical, conveyance, light, and weather-ability. Normal items incorporate lighting and optical applications. PMMA is once in a while referred to as acrylic glass as it is a lightweight, break safe choice to glass. Advantages include:

- Protection from UV radiation and enduring

- High refractive list and clearness

- Incredible light contagiousness

- Has the best surface hardness of any plastic, making it scratch safe

- Colors can be added to get a specific tone

- Chemical resistance

Pondering the needs of your part while attempting to remember the individual attributes of every material can make the cycle overpowering, particularly, with another measure of item configuration.

Plastic Resin Injection Moulding:

While examining plastic injection moulding, glass-filled plastic is usually used to improve part quality and inflexibility. The one issue that can happen with glass-filled plastic parts is expanded weakness because of critical enhancements in the part's quality and inflexibility.

Moreover, glass fill rates can run a considerable amount, which will influence the last part's properties as needs be. In case you're thinking about utilizing a glass-filled in the plastic cut cycle, it's essential to take note of that including a glass-filled gum includes quality, yet in addition acts chances like glass filaments can possibly cause inner anxieties and distorting, just as fill rate, cooling rate and psychologist rate issues.

At Novel Mould, we are devoted to helping you give a superior item to your clients by offering you extraordinary assistance and commendable quality each time you submit a request with us. We're certain we can assist you with your metal part fabricating needs paying little mind to your industry. To discover how we can put our innovative metalworking machines and mastery to work for you now, simply get in touch with plastic injection moulding manufacturing online today.